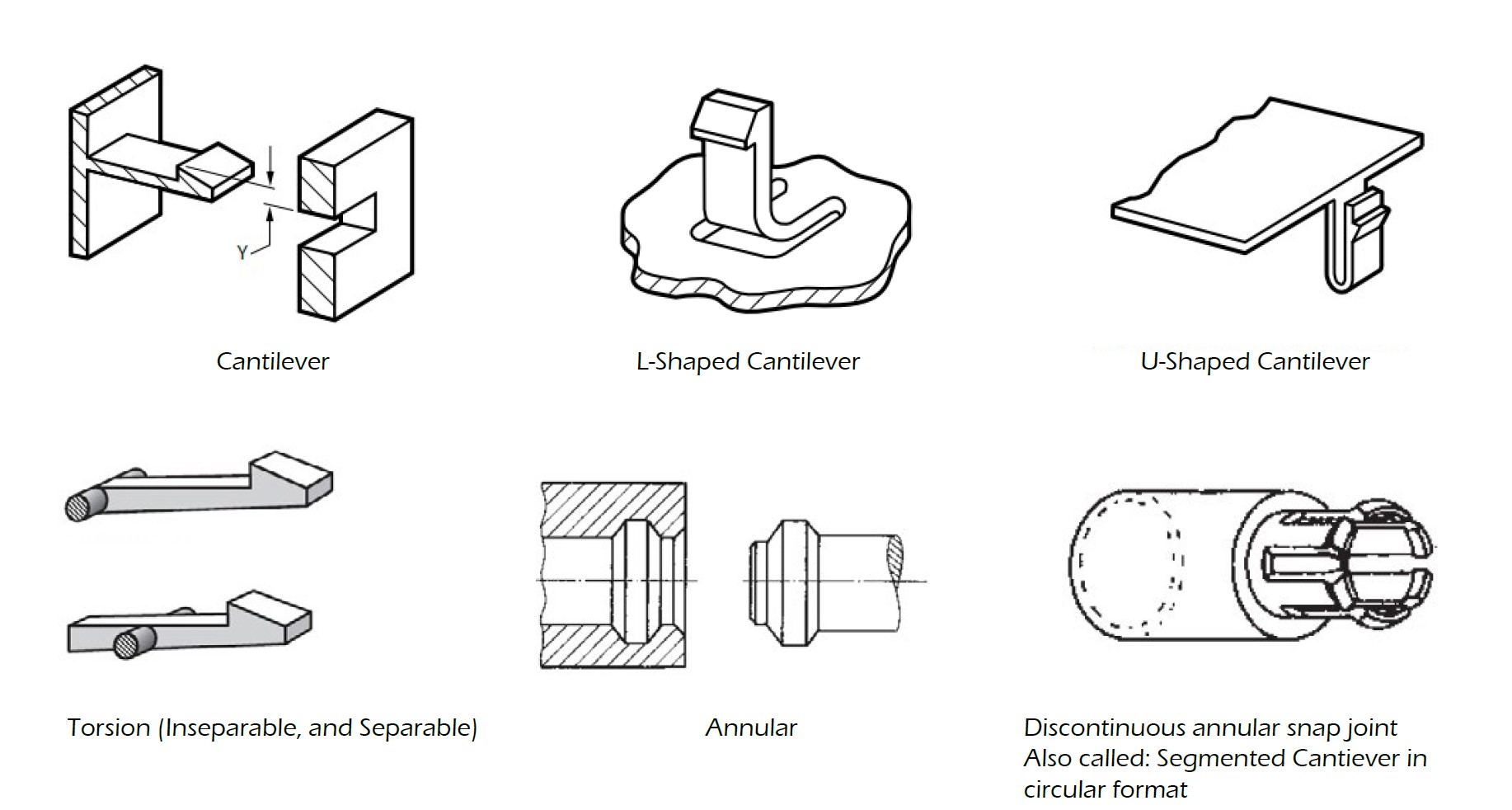

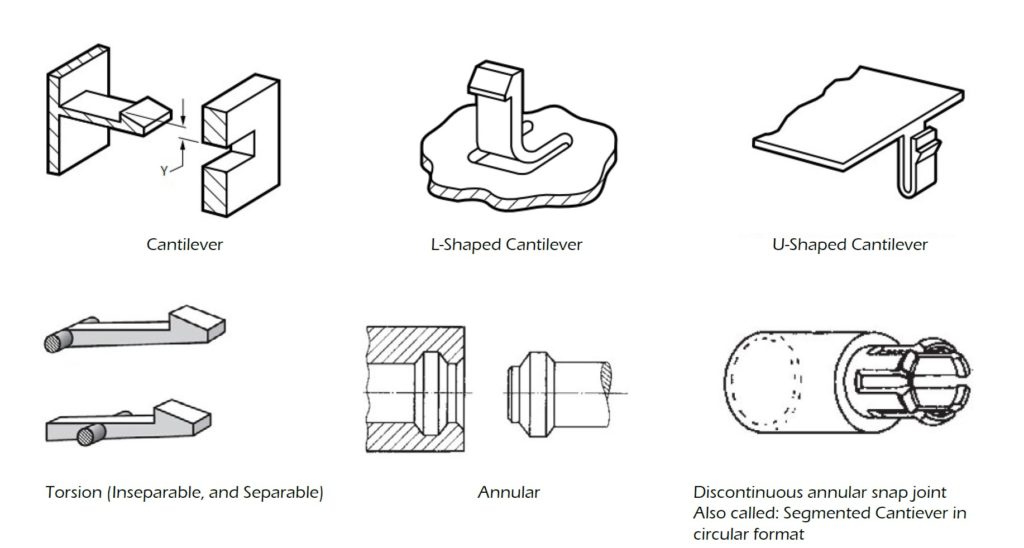

An assignment during my work hours in the Jefferson student prototyping lab was to investigate the ideal clearances for a snap-fit produced on the Stratasys FDM for student prototyping. I created a series of test profiles that evaluated some ideal clearances and tolerances for snap dimensions and compiled that information into a guide to help students quickly implement the snap-fit features and hopefully achieve testable results on the first pass.

I’ve posted the guide here, as I found lots of useful information during this research. I’ve also posted the most relevant reference sources for more information in case the project you’re working isn’t served by this cursory guide.