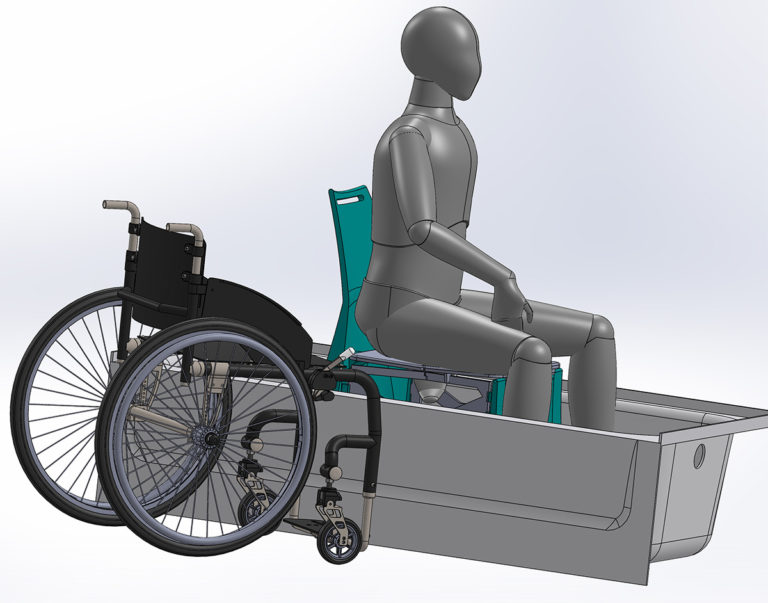

This project was to assist the Prosthetic and Orthotics department in supporting patients while they are being fitted for lower limb prosthetics. Currently the prosthetists are using a 40 year old cast aluminum 2-piece support that supports the weight of the individual while being fitted. Those cast supports are wearing out and alternatives are few. We worked on creating an additive manufactured solution that could be produced at HERL in their SLS and could be modified and updated as needed.

The beginning stages of this project involved gaining a solid understanding of the current supports features and the requirements of the P&O team. I created a 3D model of the current device using precise measurement and some trial and error to yield a function 3D model. We then set about with making small innovations and through iterative prototyping created some useful supports. The project is ongoing and improvements continue!